联系我们

-

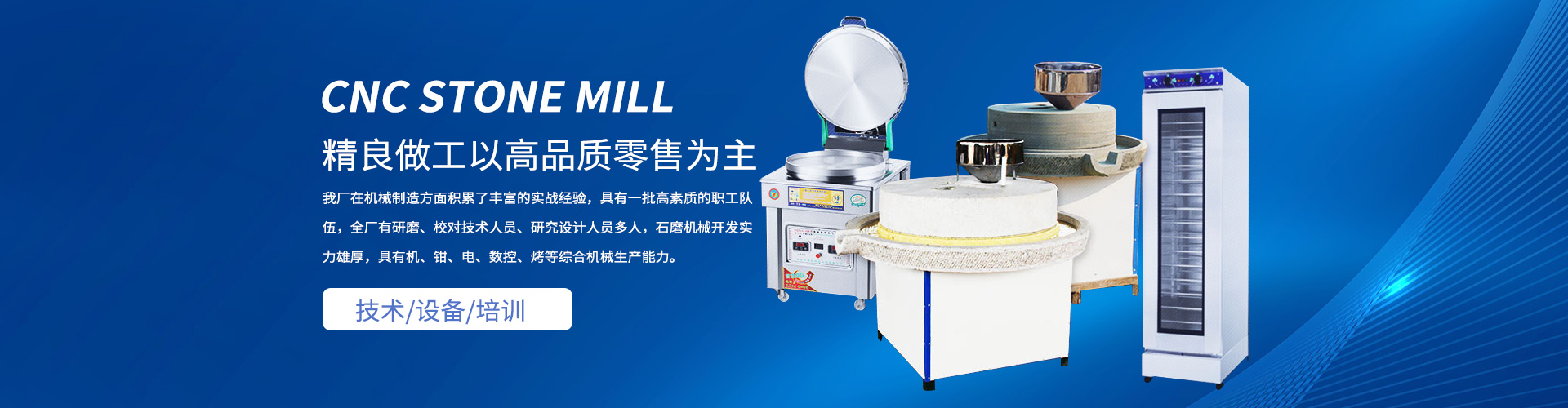

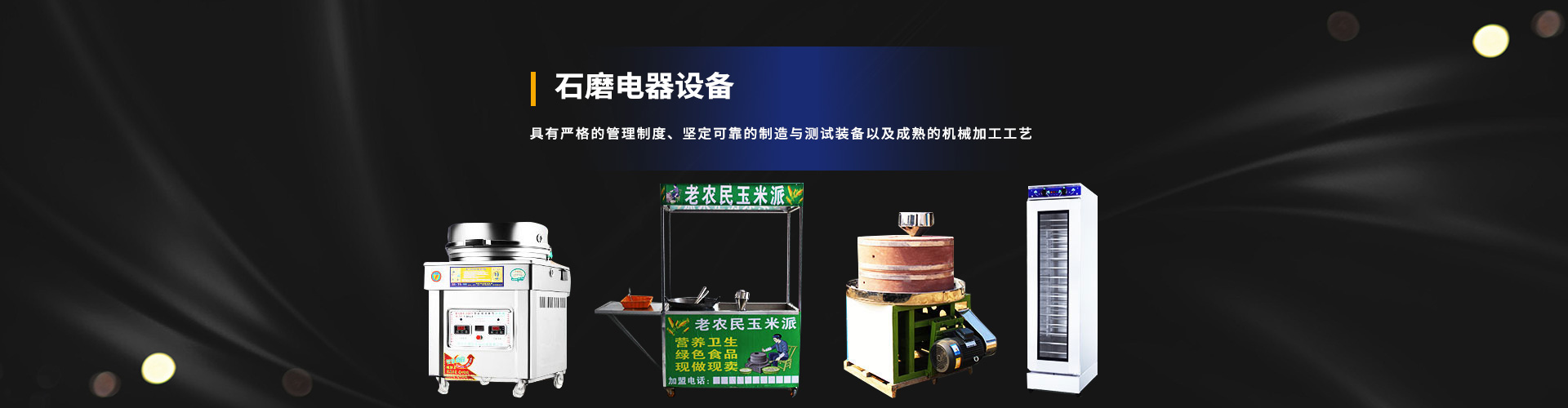

济南中阳石磨电器有限公司

- 联系:和经理

- 电话:17116125111

- 手机:17116125111

- 邮箱:3471464452@qq.com

- 网址:http://www.zysmcn.com

- 厂址:山东省济南市章丘区相公庄镇

石磨面粉机是如何进行制作面粉的?

来源:http://www.zysmcn.com/发布时间:2021-03-08

石磨面粉机制粉有多种工序,制粉流程影响着制粉工艺的效果,下面我们了解一下它的制粉流程设计的原则:

石磨面粉机制粉有多种工序,制粉流程影响着制粉工艺的效果,下面我们了解一下它的制粉流程设计的原则:

There are many kinds of working procedures for stone flour machine-made flour. The milling process affects the effect of milling process. Let's understand the design principles of milling process

1、采用合理的制粉方法。根据产品的质量要求、原料的品质、生产规模,以及单位产量、电耗指标等,确定合理的制粉方法,即制粉流程的长度、宽度和清粉范围。

1. Reasonable milling method should be adopted. According to the product quality requirements, raw material quality, production scale, unit output and power consumption index, the reasonable milling method is determined, that is, the length, width and cleaning range of milling process.

2、流量平衡。石磨面粉机制粉流程中各设备、各系统的配备,应根据各系统物料的工艺性质及其数量来决定,使负荷合理。

2. Flow balance. In order to make the load reasonable, the equipment and system should be determined according to the technological properties and quantity of materials in each system.

3、质量平衡。将粒度接近、品质相近的物料合并处理,以简化制粉流程,方便操作。不同品质要求的产品对在制品分离和组合的要求不一,质量平衡直接影响产品质量和出率。

3. Mass balance. The materials with similar particle size and quality are combined to simplify the milling process and facilitate operation. Products with different quality requirements have different requirements for separation and combination of WIP, and quality balance directly affects product quality and yield.

4、循序后推:制粉流程红对在制品的处理不能有回路,一般应逐道循序后推的原则。

4. Step by step backward: there should be no loop for the processing of work in process in the milling process. Generally, the principle of step by step backward should be adopted.

5、保证工艺过程的连续、稳定和灵活性。净麦、吸风粉及成品打包前应设一定容量的缓冲仓,以保证生产的连续性;设备配置和选用应考虑原料、气候、产品的变化,保证生产的稳定和适应性;工艺中可设置活路,是工艺具有一定的灵活性。

5. Ensure the continuity, stability and flexibility of the process. A buffer bin with a certain capacity should be set up before the packaging of wheat flour, suction powder and finished products to ensure the continuity of production; the changes of raw materials, climate and products should be considered in the configuration and selection of equipment to ensure the stability and adaptability of production; the flexible path can be set in the process, which means the process has a certain flexibility.

6、节省投资,降低消耗,清洁生产。制粉流程设计中应选用低耗设备,在保证产量和质量情况下尽量简化制粉流程,减少设备数量、降低能耗。工艺设计中还应注重清洁生产,保证产品卫生。

6. Save investment, reduce consumption, clean production. High efficiency and low consumption equipment should be selected in the design of pulverizing process. Under the condition of ensuring the output and quality, the pulverizing process should be simplified as much as possible to reduce the number of equipment and energy consumption. Cleaner production should also be paid attention to in process design to ensure product health and safety.

以上就是石磨面粉机制粉流程,面粉机研制粉,要根据制粉流程制做,来保证制粉效果。

The above is the milling process of stone mill flour machine, flour machine development flour, according to the milling process, to ensure the milling effect.

相关新闻

- 提高香油石磨机的出油率有方法2022-05-30

- 石磨豆浆机特点优点相关内容介绍2022-05-29

- 面粉石磨机保证加工制品的纯度方法2022-05-29

- 芝麻酱石磨机的四步使用方法2022-05-27

相关产品