联系我们

-

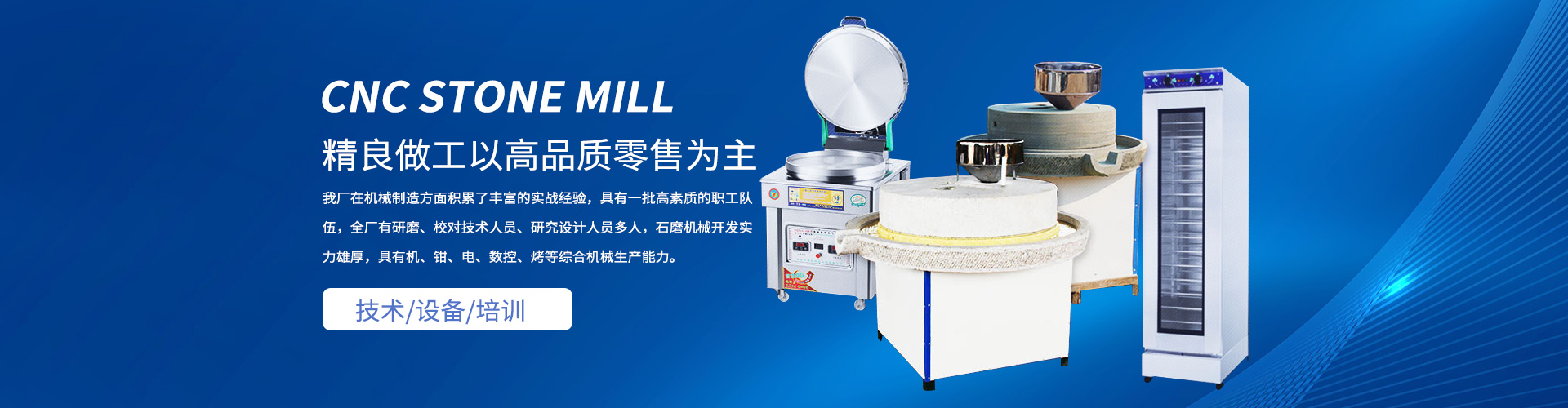

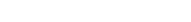

济南中阳石磨电器有限公司

- 联系:和经理

- 电话:17116125111

- 手机:17116125111

- 邮箱:3471464452@qq.com

- 网址:http://www.zysmcn.com

- 厂址:山东省济南市章丘区相公庄镇

面粉石磨机的维修要注意什么?

来源:http://www.zysmcn.com/发布时间:2021-01-16

1 经常检查轴承温度,若温度过高,应检查润滑和传动部分是否正常,轧距是否过紧等。及时查明原因,采取相应措施,情况严重时应停机检查。1

1.经常检查轴承温度,若温度过高,应检查润滑和传动部分是否正常,轧距是否过紧等。及时查明原因,采取相应措施,情况严重时应停机检查。

1. Check the bearing temperature frequently. If the temperature is too high, check whether the lubrication and transmission parts are normal, and whether the rolling distance is too tight. Find out the causes in time, take corresponding measures, and stop the machine for inspection when the situation is serious.

经常检查传动带的松紧程度,皮带过松会降低传动效率而影响研磨效果,过紧则容易引起轴承发热,增加动力消耗,降低传动带的使用寿命。

Often check the tightness of the belt. Too loose belt will reduce the transmission efficiency and affect the grinding effect. Too tight belt will easily cause bearing heating, increase power consumption and reduce the service life of the belt.

各种传动部件必须紧固可靠,拆卸或安装应使用专用工具,禁止用手锤等工具直接击打。

All kinds of transmission parts must be fastened and reliable. Special tools shall be used for disassembly or installation. It is forbidden to strike directly with hammers and other tools.

不忘检查气动元件,要经常检查气路中各气动元件,气路及连接处是否有漏气或损坏,同时要检查供气压力是否符合要求,对同步带 的使用情况也要经常检查,若发现过紧、过松、跳动、跑偏、磨损严重等情况,应及时调整、检修或更换。

Do not forget to check the pneumatic components. Always check the pneumatic components in the air circuit, whether there is leakage or damage in the air circuit and the connection. At the same time, check whether the air supply pressure meets the requirements. The use of the synchronous belt should also be checked frequently. If it is found that it is too tight, too loose, jumping, deviation, serious wear and other conditions, it should be adjusted, repaired or replaced in time.

定期有序地更换面粉机磨辊,磨辊不能一次更换过多,同时磨辊的直径不能差别过大,齿辊的角、斜度、齿数要与规定相符,要留有一定的齿顶平面。光辊各段锥度要 准确且符合规定要求,表面粗糙度要均匀一致。更换磨辊后,应按各系统磨粉机的要求,用塞尺检查,粗调其轧距。

Replace the mill roll regularly and orderly. The mill roll should not be replaced too much at one time. At the same time, the diameter of the mill roll should not be too different. The angle, slope and number of teeth of the toothed roll should be consistent with the regulations, and a certain tooth top plane should be left. The taper of each section of the smooth roller shall be accurate and meet the specified requirements, and the surface roughness shall be uniform. After replacing the grinding roller, check with feeler gauge and roughly adjust the rolling distance according to the requirements of grinding machine of each system.

本文由豆浆石磨机为您提供,我们的网站是:http://www.jylmjz.com将以全心全意的热情为您提供服务,欢迎您的访问!

This article is provided for you by soybean milk stone mill http://www.jylmjz.com We will serve you wholeheartedly and warmly. Welcome to visit!

相关新闻

- 提高香油石磨机的出油率有方法2022-05-30

- 石磨豆浆机特点优点相关内容介绍2022-05-29

- 面粉石磨机保证加工制品的纯度方法2022-05-29

- 芝麻酱石磨机的四步使用方法2022-05-27

相关产品