联系我们

-

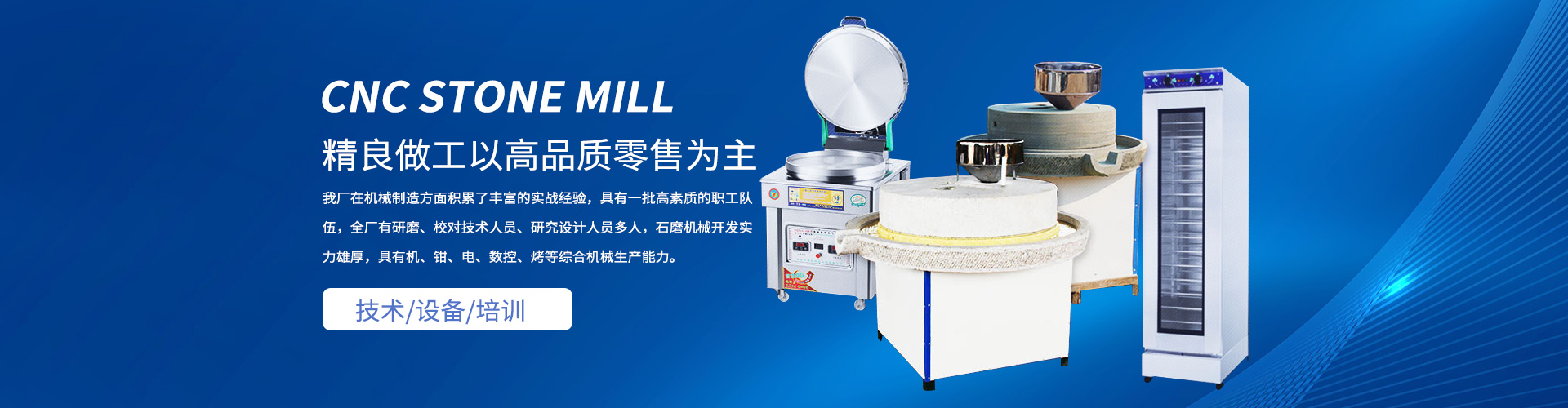

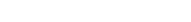

济南中阳石磨电器有限公司

- 联系:和经理

- 电话:17116125111

- 手机:17116125111

- 邮箱:3471464452@qq.com

- 网址:http://www.zysmcn.com

- 厂址:山东省济南市章丘区相公庄镇

面粉石磨机生产会忽视哪些重要问题

来源:http://www.zysmcn.com/发布时间:2021-10-13

在面粉石磨机的生产过程中,物料需要经过很多道工序,但是这么的工序中,有些工作人员由于对细节部位把控不够,所以容易忽略一些细节部位,

在面粉石磨机的生产过程中,物料需要经过很多道工序,但是这么的工序中,有些工作人员由于对细节部位把控不够,所以容易忽略一些细节部位,影响设备的正常生产。那么在石磨面粉机械的生产中有哪些容易忽视的细节呢?

In the production process of flour stone mill, materials need to go through many processes, but in such processes, some staff are easy to ignore some detail parts because they do not control the detail parts enough, which affects the normal production of the equipment. So what are the details that are easy to ignore in the production of stone flour machinery?

配麦是全自动石磨面粉机生产加工前的第道工序,合理的配麦,起到资源有效利用的作用,避免小麦出现浪费的现象。合理的配麦,还有助于面粉质量的稳定和生产效率的提高。合理的对小麦进行搭配,有助于生产过程的顺利进行,从而提高全自动石磨面粉机的加工质量,这也是配麦这个加工细节的重要意义。

Wheat blending is the first process before the production and processing of automatic stone mill flour machine. Reasonable wheat blending plays a role in the effective utilization of resources and avoids the waste of wheat. Reasonable wheat blending also contributes to the stability of flour quality and the improvement of production efficiency. Reasonable collocation of wheat is conducive to the smooth progress of the production process, so as to improve the processing quality of the automatic stone mill flour machine, which is also of great significance to the processing details of wheat blending.

控制箱是石磨面粉机的控制设备,操作的时候有定风险。位置过低,小孩轻易能碰到控制箱,容易发生事故,位置太高又操作不便。控制箱在选择位置的时候,定要选择定的高度和合适的位置。

The control box is the control equipment of the stone flour mill, which has certain risks during operation. The position is too low. Children can easily touch the control box, which is prone to accidents. The position is too high and inconvenient to operate. When selecting the position of the control box, be sure to select the fixed height and appropriate position.

要注意的是石磨面粉机械磨辊间隙问题,具体的调整步骤是合闸、拉近外螺母,压缩调整弹簧,保证两个弹簧的压力一致。目测或借助工具检测间隙是否一致。大方向上调整好了,接下来就是细节上的微调,向均匀靠拢。

The first thing to pay attention to is the gap between the grinding rollers of the stone mill flour machinery. The specific adjustment steps are closing, closing the outer nut, compressing the adjustment spring to ensure that the pressure of the two springs is the same. Check whether the clearance is consistent by visual inspection or with the help of professional tools. After the general direction is adjusted, the next step is to fine tune the details and move closer to the uniform direction.

调紧轧距,转动三角皮带,观察纸条被磨辊轧的痕迹是否均匀一致。如果痕迹不均匀,可调节拉杆上的螺母,使慢辊与快辊两端平行。经上述初调和细调后,还要在石磨面粉机械工作检查研磨后物料的破碎是否均匀;如果还不均匀,要通过调节拉杆外端螺母来调整弹簧的压力。

Tighten the rolling distance, rotate the V-belt, and observe whether the marks of the paper strip rolled by the grinding roll are uniform. If the marks are uneven, adjust the nut on the pull rod to make the slow roll parallel to the two ends of the fast roll. After the above initial and fine adjustment, it is also necessary to work in the stone mill flour machinery to check whether the crushed materials are uniform after grinding; If it is not uniform, adjust the spring pressure by adjusting the nut at the outer end of the pull rod.

石磨面粉机械安装好之后,调整的顺序要先从磨辑开始,这也是加工面粉的主要的部件。两个辐之间的距离是决定面粉粗细的重要因素,因此,调整对轮之间的距离非常重要。其次,还要调整球形螺丝旁边的偏心套,需要把平板的四个角压平,然后固定偏心套,这时的偏心套也是角度刚好的。把判断距离的厚薄规放在两个辐之间,把它们之间的距离调整到合适状态。

After the installation of stone flour machinery, the order of adjustment should start with grinding, which is also the main component of flour processing. The distance between the two spokes is an important factor in determining the thickness of flour. Therefore, it is very important to adjust the distance between the opposite wheels. Secondly, the eccentric sleeve next to the spherical screw shall be adjusted. The four corners of the flat plate shall be flattened, and then the eccentric sleeve shall be fixed. At this time, the eccentric sleeve is also at the right angle. Put the thickness gauge for judging the distance between the two spokes and adjust the distance between them to an appropriate state.

如今经过科技人员不断的尝试和调整之后,新型的、更加有效的面粉机出世了。它能够实现并肩杂彻底与净粮分离,为后道加工工序奠定了良好的质量基础,从而能够保证原粮的清理效果以及后路的效果明显提高。总体上,石磨面粉加工设备的清粮工艺实现了无论是从效率、产量还是效果上,都有了明显的提高,也保证了设备的加工质量和效益。

Now, after continuous attempts and adjustments by scientific and technological personnel, a new and more effective flour machine has been born. It can realize the complete separation of raw grain and clean grain, and lay a good quality foundation for the subsequent processing process, so as to ensure that the cleaning effect of raw grain and the effect of the back road can be significantly improved. In general, the grain cleaning process of stone mill flour processing equipment has been significantly improved in terms of efficiency, yield and effect, and also ensured the processing quality and benefit of the equipment.

相关新闻

- 提高香油石磨机的出油率有方法2022-05-30

- 石磨豆浆机特点优点相关内容介绍2022-05-29

- 面粉石磨机保证加工制品的纯度方法2022-05-29

- 芝麻酱石磨机的四步使用方法2022-05-27

相关产品